LCD 10A 12/24V Solar Panel Battery Charger Controller (QWP-SR-HP2410A)

WHAT IS A SOLAR CHARGE CONTROLLER?

WHY DO I NEED ONE?

A charge controller, or charge regulator is basically a voltage and/or current regulator to keep batteries from overcharging. It regulates the voltage and current coming from the solar panels going to the battery. Most "12 volt" panels put out about 16 to 20 volts, so if there is no regulation the batteries will be damaged from overcharging. Most batteries need around 14 to 14.5 volts to get fully charged.

DO I ALWAYS NEED A CHARGE CONTROLLER?

Not always, but usually. Generally, there is no need for a charge controller with the small maintenance, or trickle charge panels, such as the 1 to 5 watt panels. A rough rule is that if the panel puts out about 2 watts or less for each 50 battery amp-hours, then you don't need one.

For example, a standard flooded golf car battery is around 210 amp-hours. So to keep up a series pair of them (12 volts) just for maintenance or storage, you would want a panel that is around 4.2 watts. The popular 5 watt panels are close enough, and will not need a controller. If you are maintaining AGM deep cycle batteries, such as the Concorde Sun Xtender then you can use a smaller 2 to 2 watt panel.

WHY 12 VOLT PANELS ARE 17 VOLTS

The obvious question then comes up - "why aren't panels just made to put out 12 volts". The reason is that if you do that, the panels will provide power only when cool, under perfect conditions, and full sun. This is not something you can count on in most places. The panels need to provide some extra voltage so that when the sun is low in the sky, or you have heavy haze, cloud cover, or high temperatures*, you still get some output from the panel. A fully charged "12 volt" battery is around 12.7 volts at rest (around 13.6 to 14.4 under charge), so the panel has to put out at least that much under worst case conditions.

*Contrary to intuition, solar panels work best at cooler temperatures. Roughly, a panel rated at 100 watts at room temperature will be an 83 watt panel at 110 degrees.Detailed information on MPPT charge controllers.

The charge controller regulates this 16 to 20 volts output of the panel down to what the battery needs at the time. This voltage will vary from about 10.5 to 14.6, depending on the state of charge of the battery, the type of battery, in what mode the controller is in, and temperature. (see complete info on battery voltages in our battery section).

USING HIGH VOLTAGE (GRID TIE) PANELS WITH BATTERIES

Nearly all PV panels rated over 140 watts are NOT standard 12 volt panels, and cannot (or at least should not) be used with standard charge controllers. Voltages on grid tie panels varies quite a bit, usually from 21 to 60 volts or so. Some are standard 24 volt panels, but most are not.

What happens when you use a standard controller

Standard (that is, all but the MPPT types), will often work with high voltage panels if the maximum input voltage of the charge controller is not exceeded. However, you will lose a lot of power - from 20 to 60% of what your panel is rated at. Charge controls take the output of the panels and feed current to the battery until the battery is fully charged, usually around 13.6 to 14.4 volts. A panel can only put out so many amps, so while the voltage is reduced from say, 33 volts to 13.6 volts, the amps from the panel cannot go higher than the rated amps - so with a 175 watt panel rated at 23 volts/7.6 amps, you will only get 7.6 amps @ 12 volts or so into the battery. Ohms Law tells us that watts is volts x amps, so your 175 watt panel will only put about 90 watts into the battery.

Using an MPPT controller with high voltage panels

The only way to get full power out of high voltage grid tie solar panels is to use an MPPT controller. See the link above for detailed into on MPPT charge controls. Since most MPPT controls can take up to 150 volts DC (some can go higher, up to 600 VDC) on the solar panel input side, you can often series two or more of the high voltage panels to reduce wire losses, or to use smaller wire. For example, with the 175 watt panel mentioned above, 2 of them in series would give you 46 volts at 7.6 amps into the MPPT controller, but the controller would convert that down to about 29 amps at 12 volts.

CHARGER CONTROLLER TYPES

Charge controls come in all shapes, sizes, features, and price ranges. They range from the small 4.5 amp (Sunguard) control, up to the 60 to 80 amp MPPT programmable controllers with computer interface. Often, if currents over 60 amps are required, two or more 40 to 80 amp units are wired in parallel. The most common controls used for all battery based systems are in the 4 to 60 amp range, but some of the new MPPT controls such as the Outback Power FlexMax go up to 80 amps.

- Product Features

- 12V/ 24 V system voltages are automatically recognized.

- An upgraded 3-stage PWM charging algorithm is adopted. Application of an equalizing charging to the battery periodically or when over discharged, can effectively prevent the battery from non-equalization and sulfuration, thus extending the battery's service life.

- With temperature compensation employed, charging parameters can be automatically adjusted.

- A wide range of load working modes facilitate the product's application to different types of load.

- The product provides overcharge, over-discharge, overload protection, as well as short-circuit protection.

- By virtue of an advanced load starting method, large-capacitance loads can be started smoothly.

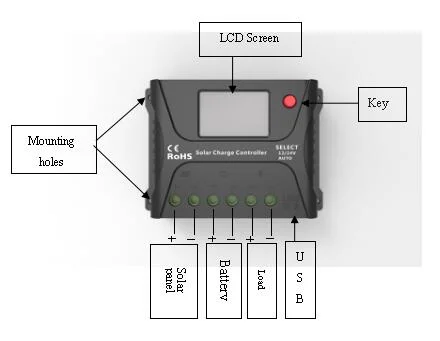

- The product provides a dot matrix graphic LCD screen and a human-machine interface with a key.

- The user-friendly design of browser and dynamic interfaces ensure convenient and intuitive operations.

- Boasting an industrial grade design, the product can function well in various tough conditions.

- TVS lighting protection is adopted.

- Panel Structure

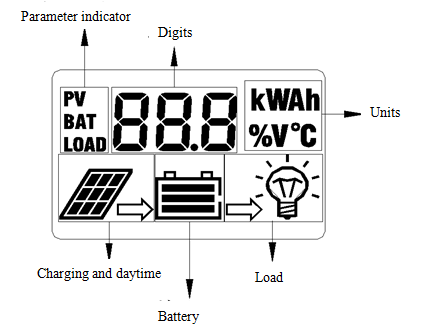

- LCD Screen Illustration

-

- Operation Instructions

- Step 1: Connect the battery. If the connection is correct, the controller screen lights up; otherwise, check whether the connection is correct.

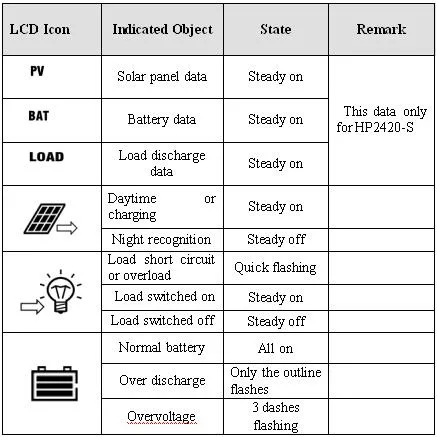

- Step 2: Connect the solar panel. If sunlight is present and strong enough (the solar panel voltage is greater than battery voltage), the sun icon on the LCD screen is on; otherwise, check whether the connection is correct.

- Step 3: Connect the load. Connect the load leads to the controller's load output terminal, and the current shall not exceed the controller's rated current.

- State Indicators

4.

- Technical Data Sheet

| Model | HP2410 | HP2420 | HP2420-S |

| Rated current | 10A | 20A | 20A |

| current display function | No | No | Yes |

| System voltage | Automatic recognition of 12 V/ 24 V | ||

| No-load loss | < 10mA/12V;< 12mA/24V | ||

| Max. Solar energy input voltage | <55V | ||

| Max. voltage at the battery end | <35V | ||

| Overvoltage protection | 17.0V;×2/24V; | ||

| Equalizing charging voltage | 14.6V;×2/24V; | ||

| Boost charging voltage | 14.4V;×2/24V; | ||

| Floating charging voltage | 13.8V;×2/24V; | ||

| Charging recovery voltage | 13.2V;×2/24V; | ||

| Over-discharge recovery voltage | 12.6V;×2/24V; | ||

| Over-discharge voltage | 11.1V;×2/24V; | ||

| Equalizing charging interval | 30days | ||

| Equalizing charging time | 1H | ||

| Boost charging time | 2H | ||

| Temperature compensation | -3.0mV/ºC/2V | ||

| Light control voltage | Light control on 5V, ×2/24V; light control off 6V, ×2/24V; | ||

| Light control judgment time | 1minute | ||

| Operating temperature | -25ºC to +55ºC; | ||

| IP protection degree | IP30 | ||

| Net weight | 100g | 160g | |

| Protection functions | Solar panel short circuit and reverse-connection protection | ||

| Over-temperature, overload and short circuit protection | |||

| Dimensions | 103×71×36(mm) | 130×75×38 (mm) | |

- Error Code List

| Code on LCD screen | Corresponding error |

| E0 | No error |

| E1 | battery over-discharging |

| E2 | battery overvoltage |

| E4 | Load short circuit |

| E5 | Overload |

| E6 | Controller inner temperature over heat |

- Common Problems and Solutions

| Symptoms | Causes and Solutions |

| LCD screen does not light up. | Check whether the battery is correctly connected. |

| Incomplete display or no renewal on LCD screen | Check whether the ambient temperature is too low and whether the display recovers when the temperature rises. |

| No charging with sunlight present | Check whether the solar panel is correctly connected, and contact is good and reliable. Check whether the solar panel voltage falls below the battery voltage. |

| The battery icon flashes quickly, and there is no output. | System overvoltage. Check whether the battery voltage is too high. |

| The battery icon flashes slowly, and there is no output. | The battery is over-discharged, and will recover after recharged adequately. |

| The load icon flashes quickly, and there is no output. | The load's power exceeds the rated value or the load is short-circuited. After the problem is solved, long press the key or wait until it recovers automatically. |

| Other symptoms | Check whether wiring is sound and reliable, and system voltage is correctly recognized. |

5. About us:

Guangzhou Queenswing Solar Energy Co. Ltd. Is a professional manufacturer and exporter of solar products including power inverter, solar charge controller, solar panel and solar battery in China. To provide high-quality product and considerate service is always our basic policy. We believe high quality creates business and progress is from improvement.

Main products:

Pure sine wave power inverter

Modified sine wave power inverter

UPS power inverter with charger

Car power inverter

Solar charge controller

Solar panel

Solar battery

Our power inverter and solar products are exported to most global coutries and get good reputation because of our favorable quality and stable performance.

6. Payment Terms:

T/T, Western Union, Money Gram

Production arranged after receipt of payment.

Lead Time:

Sample order will be delivered within 7 working days.

Order quantity below 100PCS, delivery time is 7-15 working days.

Container order will be delivered within 15-30 working days.

Shipment:

Courier: FedEx, DHL, TNT, UPS, Aramex, EMS ect.

Forwarder: By sea / air or Customer designated

7. Contact us: